Current location:Home > high pressure rotary shaft seals >

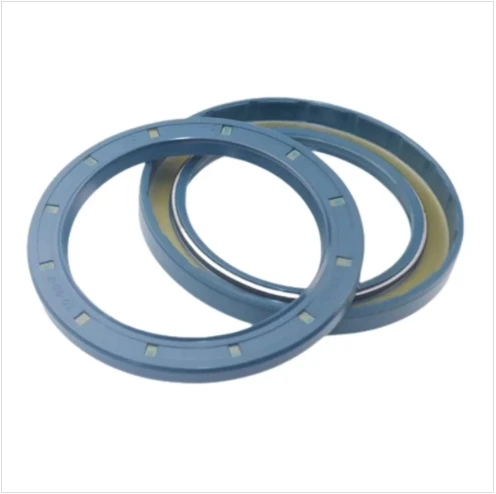

high pressure rotary shaft seals

2025-08-14 04:59

2025-08-14 04:57

...

2025-08-14 04:54

2025-08-14 04:39

2025-08-14 03:50

2025-08-14 03:50

2025-08-14 03:31

2025-08-14 03:12

2025-08-14 02:52

2025-08-14 02:50

Latest articles

The design and material selection of high pressure shaft seals are crucial for their performance high pressure shaft seals. Advanced materials such as polytetrafluoroethylene (PTFE) and silicone rubber are frequently employed due to their excellent resistance to chemicals, temperature fluctuations, and wear. Furthermore, the geometry of the seal must be optimized to withstand the extreme forces exerted by high-pressure fluids while minimizing friction and heat generation.

high pressure shaft seals. Advanced materials such as polytetrafluoroethylene (PTFE) and silicone rubber are frequently employed due to their excellent resistance to chemicals, temperature fluctuations, and wear. Furthermore, the geometry of the seal must be optimized to withstand the extreme forces exerted by high-pressure fluids while minimizing friction and heat generation.

high pressure shaft seals. Advanced materials such as polytetrafluoroethylene (PTFE) and silicone rubber are frequently employed due to their excellent resistance to chemicals, temperature fluctuations, and wear. Furthermore, the geometry of the seal must be optimized to withstand the extreme forces exerted by high-pressure fluids while minimizing friction and heat generation.

high pressure shaft seals. Advanced materials such as polytetrafluoroethylene (PTFE) and silicone rubber are frequently employed due to their excellent resistance to chemicals, temperature fluctuations, and wear. Furthermore, the geometry of the seal must be optimized to withstand the extreme forces exerted by high-pressure fluids while minimizing friction and heat generation.Oil seals are commonly used in engines, gearboxes, hydraulic systems, and other machinery where oil or lubricants are present. They are typically installed in areas where rotating shafts or moving parts come into contact with fluids, creating a potential leak point They are typically installed in areas where rotating shafts or moving parts come into contact with fluids, creating a potential leak point They are typically installed in areas where rotating shafts or moving parts come into contact with fluids, creating a potential leak point They are typically installed in areas where rotating shafts or moving parts come into contact with fluids, creating a potential leak point

They are typically installed in areas where rotating shafts or moving parts come into contact with fluids, creating a potential leak point They are typically installed in areas where rotating shafts or moving parts come into contact with fluids, creating a potential leak point 70 90 10 oil seal. By sealing off these areas, oil seals help to maintain a consistent fluid level and prevent contamination or damage to the internal components.

70 90 10 oil seal. By sealing off these areas, oil seals help to maintain a consistent fluid level and prevent contamination or damage to the internal components.

They are typically installed in areas where rotating shafts or moving parts come into contact with fluids, creating a potential leak point They are typically installed in areas where rotating shafts or moving parts come into contact with fluids, creating a potential leak point

They are typically installed in areas where rotating shafts or moving parts come into contact with fluids, creating a potential leak point They are typically installed in areas where rotating shafts or moving parts come into contact with fluids, creating a potential leak point 70 90 10 oil seal. By sealing off these areas, oil seals help to maintain a consistent fluid level and prevent contamination or damage to the internal components.

70 90 10 oil seal. By sealing off these areas, oil seals help to maintain a consistent fluid level and prevent contamination or damage to the internal components.Another advantage of stainless steel resin anchor bolts is their ease of installation

stainless steel resin anchor bolts. With the right tools and equipment, these bolts can be quickly and securely fastened to concrete or masonry surfaces. This saves time and labor costs, making them a cost-effective solution for construction projects.

stainless steel resin anchor bolts. With the right tools and equipment, these bolts can be quickly and securely fastened to concrete or masonry surfaces. This saves time and labor costs, making them a cost-effective solution for construction projects.

In addition to their strength and durability, galvanized A325 bolts offer several advantages over other types of fasteners

structural bolts a325 galvanized. The zinc coating provides a barrier against rust and corrosion, extending the lifespan of the bolts and reducing the need for frequent maintenance and replacement. This can result in cost savings over time and contribute to the overall longevity and stability of the structure.

structural bolts a325 galvanized. The zinc coating provides a barrier against rust and corrosion, extending the lifespan of the bolts and reducing the need for frequent maintenance and replacement. This can result in cost savings over time and contribute to the overall longevity and stability of the structure.

Another noteworthy feature of chemical anchor fasteners is their versatility. They can be used in various settings, including in cracked and uncracked concrete, brick walls, and other masonry substrates. Furthermore, these anchors can often be installed in holes that are drilled with specialized tools, allowing for greater flexibility in construction designs and reducing the risk of damaging surrounding materials.

chemical anchor fastener